Have you ever wondered how that beautiful, durable bag you carry every day is made? The journey from raw materials to finished product involves a sophisticated blend of craftsmanship, technology, and quality control. At MerrisBags, we've perfected this process over 10 years, producing everything from simple totes to complex technical backpacks.

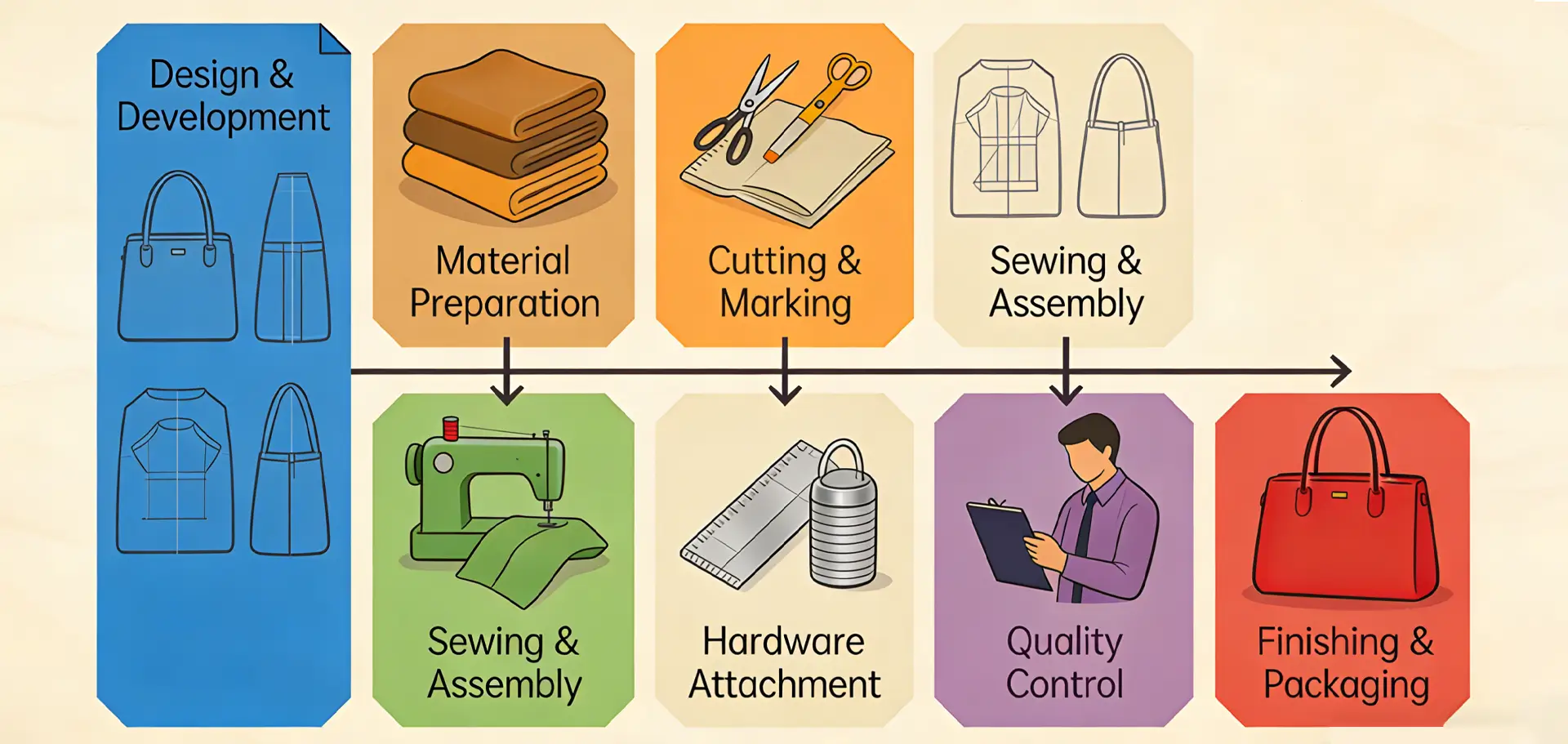

The 7-Step Bag Manufacturing Process

Every quality bag goes through seven essential stages. Let's walk through each step in detail:

Concept to Technical Specifications

1-3 WeeksThis crucial first stage transforms creative ideas into manufacturable designs. Our design team works with clients to understand their vision, target market, and functional requirements.

Digital Prototyping

Using CAD software to create 3D models and technical drawings with precise measurements.

Material Selection

Choosing the right fabrics, hardware, and trims based on durability, aesthetics, and cost requirements.

Sample Creation

Producing physical prototypes to test design, functionality, and manufacturability.

From Raw Materials to Production-Ready Components

2-5 DaysQuality begins with materials. We source premium fabrics, hardware, and components from certified suppliers, then prepare them for production.

Fabric Inspection

Checking for defects, color consistency, and texture uniformity before cutting.

Material Treatment

Applying water repellency, stain resistance, or other functional coatings as required.

Component Organization

Sorting and preparing zippers, buckles, rivets, and other hardware for efficient assembly.

Precision Pattern Cutting

1-2 DaysUsing advanced cutting technology to transform large fabric rolls into precise bag components with minimal waste.

Digital Pattern Layout

AI-powered software optimizes pattern placement to maximize material utilization (92%+ efficiency).

Laser Cutting

For precision cutting of intricate shapes and designs with clean, sealed edges.

Marking & Notching

Adding alignment marks and notches to ensure proper assembly in later steps.

Where Components Become a Bag

2-4 DaysSkilled artisans and specialized machines transform cut pieces into functional bag structures through precise sewing and assembly techniques.

Specialized Sewing Machines

Using heavy-duty, walking foot, and computerized machines for different materials and stitch types.

Sub-Assembly Creation

Building smaller components like pockets, straps, and linings before final assembly.

Main Assembly

Bringing all components together to create the complete bag structure.

Adding Functionality & Finishing Touches

1-2 DaysThis stage adds the functional elements that make the bag practical and durable for everyday use.

Zipper Installation

Precise attachment of zippers with reinforced stitching for smooth operation and longevity.

Rivets & Snaps

Installing metal hardware for strength at stress points and closure mechanisms.

Strap Attachment

Secure attachment of shoulder straps, handles, and adjustable components.

Ensuring Perfection in Every Bag

1 DayEvery bag undergoes rigorous inspection at multiple stages to ensure it meets our quality standards and client specifications.

Visual Inspection

Checking for stitching defects, fabric flaws, and alignment issues.

Functional Testing

Testing zippers, clasps, straps, and other moving parts for smooth operation.

Load Testing

Testing bags under weight to ensure structural integrity and durability.

Preparing for Delivery

1 DayThe final stage ensures each bag is perfectly presented and protected for shipping to our clients.

Final Cleaning

Removing any dust, threads, or marks from the manufacturing process.

Branding Application

Adding logos, labels, and tags as specified by the client.

Protective Packaging

Wrapping each bag to prevent damage during shipping and storage.

Quality Control: Our 7-Point Inspection System

Quality isn't an afterthought—it's built into every step of our process. Here's what we check:

Dimensional Accuracy

Every bag is measured against specifications to ensure proper size and proportions.

Stitch Quality

Checking stitch density, tension, and straightness with specialized lighting and tools.

Color & Material Consistency

Verifying color matching and material quality across all components of the bag.

Hardware Functionality

Testing zippers, buckles, and other hardware for smooth operation and durability.

Load Testing

Bags are tested with weighted contents to ensure straps, seams, and structures can handle intended use.

Final Visual Inspection

Trained inspectors examine each bag under proper lighting for any visual defects before packaging.

Custom Manufacturing vs. Standard Production

Understanding the differences helps brands choose the right approach:

Custom Manufacturing

- Higher initial setup costs but lower per-unit cost at scale

- Longer lead time for initial samples and production setup

- Complete control over design, materials, and features

- Ideal for established brands with specific requirements

Standard Production

- Lower minimum order quantities (often as low as 100 pieces)

- Faster turnaround from order to delivery

- Pre-designed options with some customization (colors, logos)

- Perfect for startups, test markets, and promotional items

Timeline: From Concept to Finished Product

A typical manufacturing timeline looks like this:

Week 1-2: Design & Sampling

Concept development, material selection, and creation of first samples for approval.

Week 3: Production Setup

Pattern making, material sourcing, and production line preparation.

Week 4-6: Manufacturing

Full-scale production with quality checks at every stage.

Week 7: Quality Control & Shipping

Final inspection, packaging, and preparation for shipment to client.

"The difference between a good bag and a great bag is in the details—the precision of the stitching, the quality of the hardware, and the rigor of the quality control. At MerrisBags, we're obsessed with these details because we know they're what our clients' customers will notice every day." – Zhang Wei, Production Manager

Conclusion: The Art & Science of Bag Manufacturing

Bag manufacturing is a fascinating blend of traditional craftsmanship and modern technology. From the initial design concept to the final quality check, each step requires specialized skills, attention to detail, and a commitment to quality.

At MerrisBags, we've spent 15+ years refining this process, investing in both our people and our technology. The result is a manufacturing capability that can produce everything from small boutique runs to large-scale commercial productions, all with the same commitment to quality and attention to detail.

Whether you're a brand looking to create your first bag collection or an established company seeking to optimize your manufacturing process, understanding these steps is the first step toward creating products that will delight your customers and stand the test of time.