The 5 Critical Quality Traps in Cosmetic Bag Manufacturing

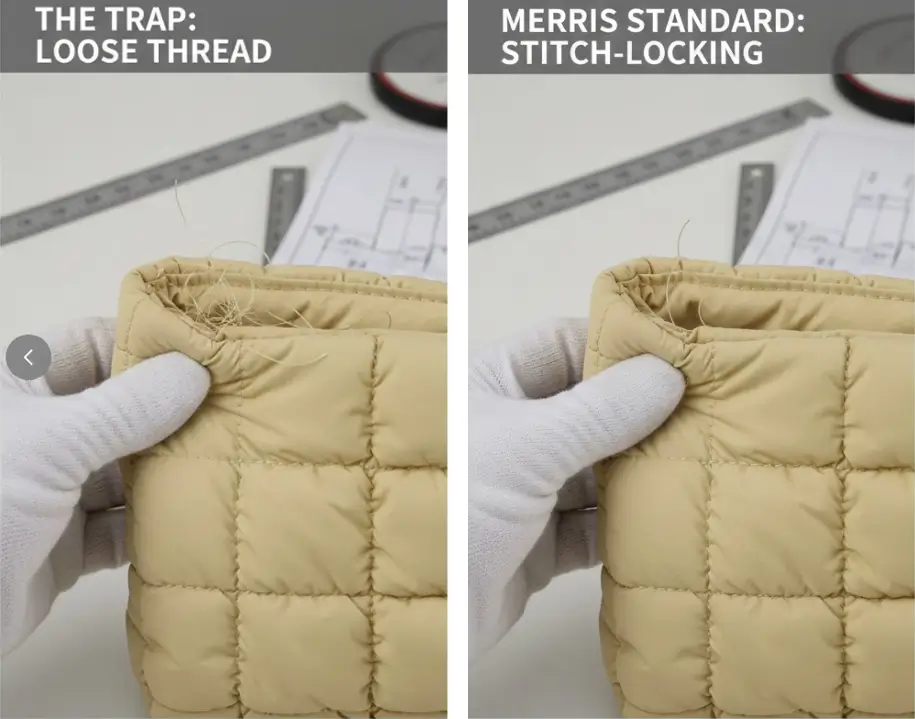

The "Loose Thread" Trap (Stitch-Locking)

The Trap: Many low-cost factories skip the critical "finishing" stage to save time. As seen in the comparison, loose threads at the edges are more than just a cosmetic mess—they indicate that the seam has not been properly terminated or locked, leading to rapid unraveling under tension.

The Domino Effect: Without professional stitch-locking, a single stray thread acts as a "rip-cord." Once it snags on a zipper or a customer's keys, the entire quilted panel can unzip, compromising both the bag's structure and your brand's quality promise.

Automated Knot-Tying

Our CNC-controlled machines execute a precise back-stitch "knot" at every seam termination to prevent fraying.

Zero-Fray Finishing

We implement a strict 100% manual inspection protocol to trim and heat-seal any remaining micro-threads.

Stress-Tested Seams

Every batch is subjected to localized pull tests to ensure the stitch-locking holds under maximum capacity loads.

How to Check: Examine the top corners and interior seams. Pull firmly on any visible thread; if the seam gaps or the thread continues to pull out, the factory has failed the stitch-locking test.

The Lining Snag (The Invisible Margin)

The Trap: To cut costs, many factories use generic, loose-fit linings. As shown in the comparison, these unanchored inner layers often bunch up, inevitably getting caught in the zipper teeth. This leading cause of zipper failure results in torn fabric and frustrated customers.

The Brand Impact: A zipper that snags due to excess material immediately devalues your product, transforming a premium gift into a functional nuisance.

Thermal Lamination

Our lining is thermally bonded to the outer shell, creating a single, taut layer that cannot shift or bunch.

3mm Safety Clearance

We engineer a precise 3mm margin between the seam and the zipper teeth, ensuring a smooth glide every time.

Structural Seam-Sealing

Internal edges are seam-sealed to provide a clean, snag-free finish that reinforces the bag's geometry.

How to Check: Fully open the bag and run the zipper back and forth. If the lining "waves" or touches the zipper teeth, it is a high-risk design prone to snags.

Polyester Grade: Pilling vs. Performance

The Trap: Budget manufacturers often use low-grade polyester that feels waxy and is prone to "pilling"—forming unsightly fuzz balls after minimal friction. As shown in the comparison, these fabrics lack structural integrity, causing the bag to look aged and worn within weeks of use.

The Brand Impact: A pilled surface suggests a cheap, disposable product. For beauty and tech brands, this lack of durability directly translates to a perceived lack of quality in your own core offerings.

Anti-Pilling Technology

We use a minimum 300D+ high-density weave that resists surface abrasion and prevents fiber shedding.

Hydrophobic Coating

Our water-resistant treatment causes liquids to bead up and roll off, protecting the fabric from deep-set stains.

UV-Stable Colorfastness

Advanced colorfast treatments ensure the material maintains its original brilliance and resists fading over time.

How to Check: Perform a "Friction Test." Rub a damp cloth firmly against the fabric ten times. If the surface feels "fuzzy" or water absorbs instantly, the material is low-grade.

Polyester Grade Comparison: Cheap vs. Premium

| Specification | Cheap Factory Standard | MerrisBags Premium Standard |

|---|---|---|

| Polyester Denier | 150D-200D (Thin) | 300D+ (High-Density) |

| Pilling Resistance | Pills after 50 rubs | No pilling after 500+ rubs |

| Water Resistance | None or basic coating | Advanced PFAS-free coating |

| Color Fastness | Fades with UV exposure | UV-resistant treatment |

| Touch & Feel | Waxy, synthetic feel | Dry, luxurious hand-feel |

Symmetry and "Geometry" Failure

The Trap: In low-end factories, workers often rely on "eyeballing" the alignment while feeding fabric through high-speed sewing machines. As shown in the comparison, even a 2mm shift during the seam-joining process results in a "leaning" bag where the diamond grids fail to meet symmetrically.

The Visual Imperfection: Misaligned geometry is an instant red flag for quality. If the diamond pattern doesn't line up perfectly across the side seams, it signals a lack of professional jigs and poor operator training, regardless of how good the material is.

Template-Assisted Feed

We use customized sewing templates (jigs) to fix the fabric in place, ensuring every diamond grid aligns perfectly before it hits the needle.

Synchronized Needle Feed

Our industrial sewing machines use synchronized feeding mechanisms to prevent fabric layers from shifting during high-speed operation.

5-Point Geometric Audit

QC inspectors use physical alignment gauges to verify symmetry at 5 critical points: the zipper start, the base corners, and the side seam junctions.

Key Insight: By using rigid sewing templates instead of relying solely on manual hand-feeding, we guarantee that every "diamond" remains mathematically centered across all bag panels.

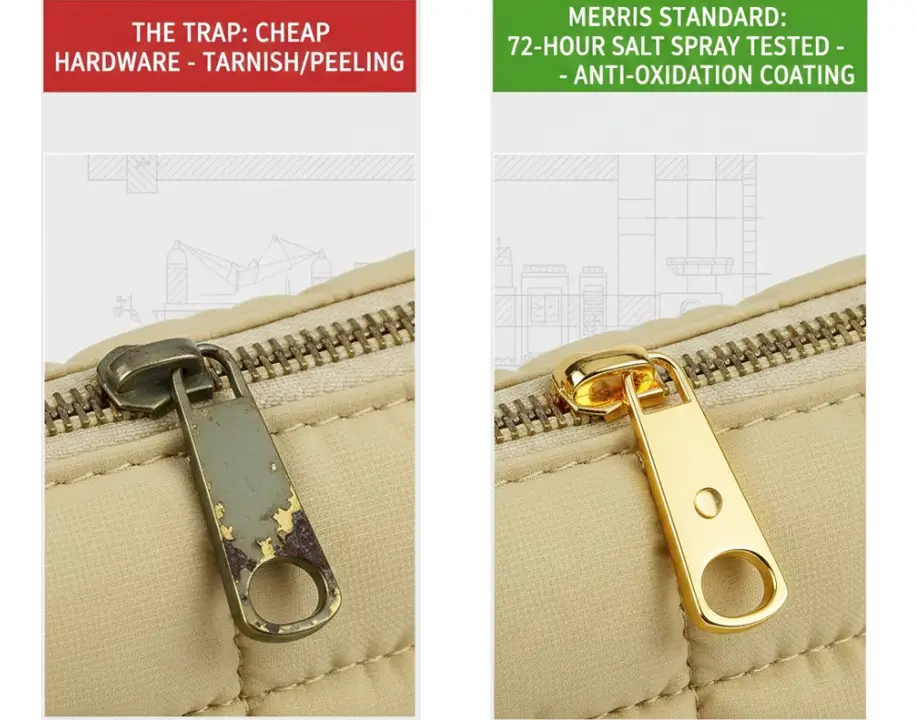

The Hardware: "Gold" That Doesn't Peel

The Trap: Cosmetic bags are primarily used in high-humidity environments like bathrooms. As shown in the comparison, cheap zinc alloy hardware with thin, low-grade plating oxidizes rapidly, leading to unsightly "peeling," surface corrosion, and a gritty zipper glide.

The Luxury Fail: Nothing devalues a premium beauty product faster than tarnished, rusted-out hardware. It suggests a lack of durability that reflects poorly on your brand's attention to detail.

High-Purity Zinc Alloy

We use Grade-A alloys with balanced copper content to provide a stable, smooth base for electroplating.

Anti-Oxidation Coating

Our 4-layer plating process (Copper + Nickel + Gold + Protective Topcoat) seals the metal against moisture.

72-Hour Salt Spray Test

Every batch is certified to withstand 72 hours of corrosive salt spray, simulating years of humid bathroom exposure.

How to Check: Scratch the back of the zipper pull with a coin. If the "gold" flakes off or reveals a dark grey metal underneath immediately, the plating lacks the necessary protective barrier.

Cosmetic Bag Factory Inspection: 6 Essential Checks

Quilting Lock Test

Pull firmly at diamond intersections. Thread should not lift or show gaps.

Zipper Snag Test

Open and close rapidly 20 times. Lining should never catch in teeth.

Pattern Alignment

Check side seams: diamond grids should match perfectly.

Water Resistance

Sprinkle water on fabric. Should bead up, not absorb.

Hardware Weight

Premium zippers have substantial weight, not hollow feel.

Lining Tautness

Interior should be smooth with no loose fabric pockets.

Your Brand's Most Intimate Ambassador

Unlike shelf packaging that gets discarded, a cosmetic bag becomes a daily companion. It travels in purses, sits on vanities, and accompanies customers on trips. Every interaction—every smooth zip, every perfectly aligned diamond, every stain that wipes clean—reinforces your brand's commitment to quality.

When you choose manufacturing partners based solely on price, you're not just risking product failures. You're risking the intimate relationship between your beauty brand and its most loyal customers.

Ready to Elevate Your Brand's Essentials?

Request a technical sample of our quilted collection. Experience the difference between bulk manufacturing and precision engineering.

Request a Technical Sample of our Quilted CollectionIndustry Specialization

10+ years focused on beauty and cosmetics packaging manufacturing.

Technical Samples

Free pre-production samples with detailed quality documentation.

Small MOQs

Minimum order quantities starting at 500 units for brand testing.

Sustainability Options

Recycled polyester and eco-friendly coating alternatives available.